Using Targets for Laser Scanning

When Should You Use Targets?

As mentioned, if coordinates are used in the project, the operator may need to scan things such as cotton spindles or brass caps. Sometimes a surveyor may place a target about where a marker may be.

Repetitive Features

Long hallways, parking garages and concrete pipes make it difficult for the scanner’s auto registration feature to lock on correctly due to the repetitive layout, and with manual registration, it may be difficult to decipher the scan location.

Specialty Rooms

Especially during field registration, features such as walls, floors and ceilings are important for pieces to the point cloud puzzle. In specialty rooms such as boiler or utility rooms, these features are extremely disrupted by pipes, conduits and other elements, making it difficult to find the true registration. Having at least three targets in view will mitigate the need to overlap walls, floors and ceilings.

Narrow Doorways

With narrow portals or doors, it can be difficult to find good overlap. Most scanners won’t record any points within one meter from the scanner. Since most doors are narrower than a meter, a tight corridor with a switch back may not offer any walls to be viewable in the scan, so the operator must rely on stitching using the ceiling and surrounding features such as smoke sensors.

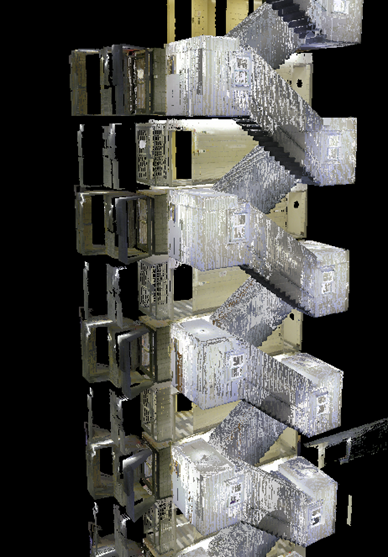

Multi-Floor Stairways

Multi-floor stairways are a combination of repetitive features and narrow portals but are a common obstacle most technicians will face. In many cases, the stairway is the feature that links multiple floors to the entire point cloud, so lining up the scans correctly is extremely crucial.

Conclusion

During registration, triangulating links between stations can help straighten the whole bundle and ensure true lineament. Single links between bundles can cause a technician to be skeptical over lineament, especially if the link is joining two larger bundles that have no other link joining them. A misalignment can cause the links to be off by a few degrees in any axis or even become undetectable later in the design process. This is unlikely due to the reliability of modern scanners such as the RTC360, the software used alongside the scanner uses extremely powerful auto registration algorithms that assist with registration.

Joining bundles from multiple scanners or stitching odd scans from returns trips can benefit from annotated targets and help give stations a location reference.

It comes down to acceptable tolerance. A minor office renovation may have more room for error, but a hospital boiler room may require extreme precision due to narrow clearances between existing pipes and conduits or even long runs to upper floors. If promises were made for extreme accuracy, you can send out your data with confidence knowing your stations are lined true.